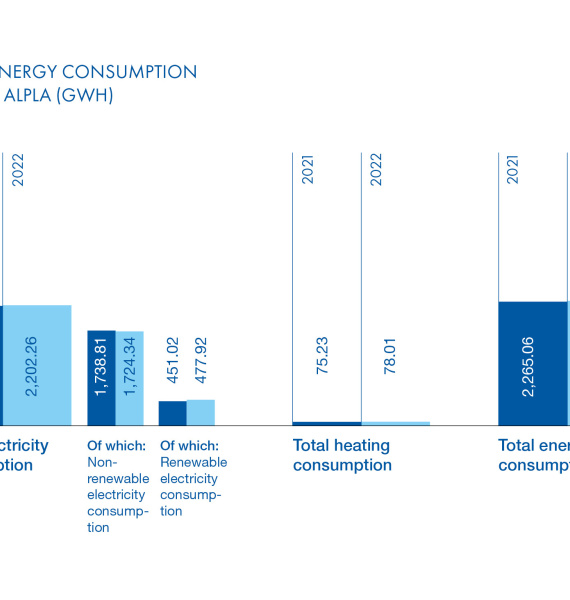

Electricity constitutes 96% of our energy consumption and it therefore significantly impacts both our overall production costs and the environment. ALPLA primarily sources electricity from the local grid, which comprises a combination of fossil fuel-based and renewable energy sources. Additionally, we strive to generate our own energy through photovoltaic systems installed on our rooftops wherever feasible. Another energy source is natural gas, which is predominantly used for heating purposes, with the occasional reliance on oil in rare cases.

In the reporting years 2021 and 2022, our global energy consumption from electricity remained constant around 2,200 GWh, despite a 4% increase in our material consumption. Western Europe accounted for the highest consumption (29%), followed by Mexico and Central America (20%) and Central Eastern Europe (11%). We report our electricity consumption data based on the invoices managed by our plants. The figures include our base plants, in-house plants, and recycling facilities.

Renewable energy

Using renewable energy in our production processes is of great importance as it contributes to environmental protection, while conserving resources, driving innovation and meeting customer requirements. By increasing renewable energy usage, ALPLA can operate sustainably and help shape a future worth living in.

Our clear goal is to gradually increase the proportion of renewable energy usage in line with the demand of our customers as well as our decarbonisation efforts. In the reporting years, the proportion of energy consumption from renewable sources was at 21–22%. This share considers only the purchased renewable energy (i.e. not taking into account the renewable energy share in the national grids) as well as self-generated renewable energy (i.e. solar panels on our rooftops).

While countries like Austria, Germany, Spain, Portugal, Poland, Mexico, Costa Rica and Panama already have plants that run on (or close to) 100% renewable energy, we are actively examining potential options to further strengthen the share of renewable energy globally. These include short-term initiatives to switch to 100% renewable energy from biomass in further plants in the UK or obtain 70% of our energy from Power Purchase Agreements (PPAs) in remaining plants in Germany from 2024 onwards.

Energy efficiency

Each year, we conduct plant energy assessments to identify the energy-saving projects with the most potential. On average, five to six sites undergo such an assessment yearly. Our experts analyse the plants’ energy consumption and energy efficiency. An individual action plan is then drawn up for each plant based on the results and in accordance with its future economic development. The savings potential following a successful assessment is around 10%. Much of the savings are made possible by modernisations and investments in new systems and machinery.

Andre Alber

Corporate Plant Engineer

‘Energy efficiency is more important than ever to meet challenging sustainability targets and reduce the risk of volatile energy prices.’

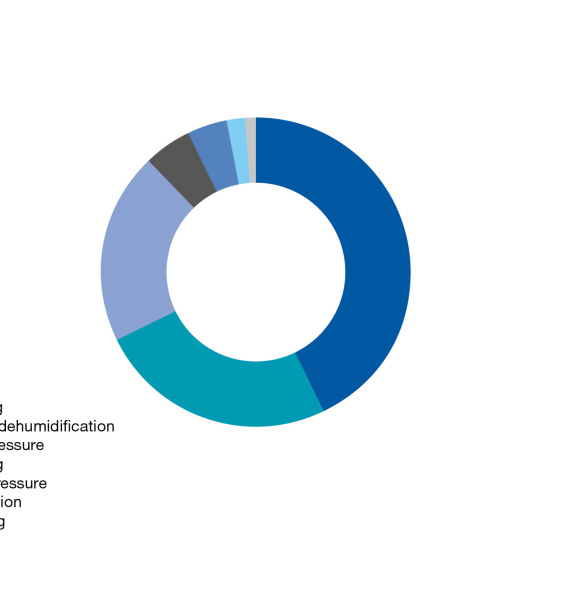

In our corporate strategy, our 2022 global energy efficiency target was to achieve 3.5% compared to our base year 2018. The year-on-year energy efficiency increase reached 0.75% and 0.69% in 2021 and 2022 respectively. The cumulative energy efficiency increase in the strategic period adds up to a total improvement of 14.3% in 2022, well above plan, which equals an amount of 114.8 GWh in energy savings. Energy efficiency improvement projects are mostly linked to electricity consumption (52%) and cooling activities (43%), with less focus on heating (5%).